The Role of Robotics in Logistics: Increasing Speed and Efficiency

In the intricate web of logistics, where time and precision define success, the integration of robotics has emerged as a game-changer. Once considered a futuristic concept, robotics is now at the heart of modern logistics, transforming how goods are moved, stored, and delivered. This revolution is not just about adopting advanced machinery; it is a journey toward creating smarter, faster, and more reliable supply chains that redefine customer expectations.

The Need for Robotics in Modern Logistics

Global supply chains have grown increasingly complex, driven by the surge in e-commerce, higher consumer expectations for speed and accuracy, and the ongoing challenges of labor shortages. These pressures demand solutions that can perform repetitive, high-precision tasks efficiently and at scale. Robotics has answered this call by automating critical logistics operations, enhancing productivity while reducing human error and costs.

Key Applications of Robotics in Logistics

1. Automated Warehousing: The New Standard

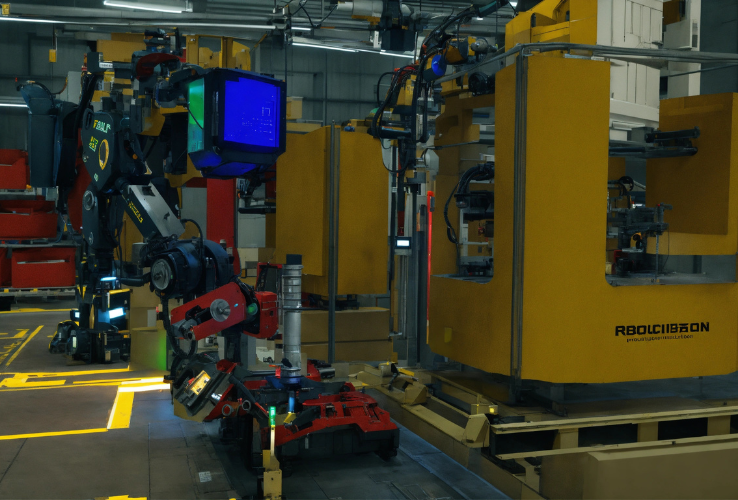

At the heart of logistics lies warehousing, a traditionally labour-intensive domain where robotics has made significant inroads. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are revolutionizing how goods are transported within warehouses. These robots navigate seamlessly through storage facilities, fetching items and delivering them to designated stations, drastically reducing the time required for manual picking.

Amazon’s use of robotics in its fulfillment centers exemplifies the transformative potential of this technology. The company’s Kiva robots, which autonomously move shelves to human workers, have significantly improved order fulfillment speed and accuracy, enabling Amazon to meet its ambitious delivery promises.

2. Order Picking and Sorting

Picking and sorting are among the most repetitive and error-prone tasks in logistics. Robotic arms equipped with advanced sensors and AI-driven vision systems are now capable of identifying and handling a wide range of items, from fragile products to irregularly shaped goods. These systems improve accuracy while minimizing damage, especially in high-volume operations.

3. Last-Mile Delivery

While robotics in warehouses has gained traction, last-mile delivery is also witnessing automation through the deployment of autonomous delivery vehicles and drones. Companies like Starship Technologies are deploying small, self-driving robots to deliver packages in urban areas, reducing costs and environmental impact. Drones are being explored as a solution for remote or hard-to-reach locations, providing unparalleled speed for urgent deliveries.

Benefits of Robotics in Logistics

1. Enhanced Speed and Efficiency

Robots can operate around the clock without fatigue, drastically reducing cycle times for picking, packing, and shipping. This continuous operation enables businesses to meet the growing demand for same-day and next-day delivery.

2. Improved Accuracy and Reliability

Human error, a common challenge in logistics, is significantly minimized with robotics. Robots’ ability to follow programmed instructions with precision ensures consistent quality and fewer errors, leading to higher customer satisfaction.

3. Cost Optimization

While the initial investment in robotics can be substantial, the long-term savings in labor costs, reduced errors, and faster processing times result in a strong return on investment (ROI). For large-scale operations, this cost efficiency can be a critical competitive advantage.

4. Scalability and Flexibility

Robots can be easily scaled up or down to meet seasonal demand fluctuations, making them an ideal solution for industries like e-commerce, where demand spikes are common.

Challenges and Considerations

Despite its many benefits, the integration of robotics in logistics is not without challenges. High upfront costs and the need for robust digital infrastructure are significant barriers for small and medium-sized enterprises (SMEs). Additionally, the successful deployment of robots depends on seamless collaboration between humans and machines, requiring comprehensive training and cultural adaptation within organizations.

Another concern is the potential displacement of jobs due to automation. However, experts argue that robotics will create opportunities for higher-skilled roles in programming, maintenance, and oversight, emphasizing the need for workforce reskilling.

The Future of Robotics in Logistics

The journey of robotics in logistics is far from over. Emerging advancements, such as AI-driven predictive analytics and machine learning, are expected to make robots even more intelligent and capable. For instance, robots are likely to handle more complex tasks, such as decision-making in dynamic environments or interacting with humans more naturally.

Additionally, collaborative robots—or cobots—are set to play a significant role. Designed to work alongside humans, cobots can enhance productivity by combining the strengths of human creativity and robotic efficiency.

Robotics: The Backbone of a Resilient Supply Chain

Robotics is no longer a luxury but a necessity for businesses seeking to thrive in the fast-paced world of logistics. By automating processes, enhancing speed and precision, and reducing costs, robotics has become a cornerstone of supply chain innovation. Companies like Amazon and Alibaba have shown that embracing robotics is not just about keeping pace with change but leading it.

As logistics leaders evaluate their operations, the integration of robotics offers an unparalleled opportunity to build resilient, scalable, and customer-focused supply chains. The journey toward automation may require investment and adaptation, but the rewards—efficiency, reliability, and competitiveness—make it an essential step forward. The future of logistics is robotic, and for those willing to innovate, the possibilities are limitless.