Solutions

Oracle E-Business Suite Manufacturing - A Comprehensive Solution for Modern Manufacturing

Manufacturing is a complex and dynamic activity that requires constant adaptation to changing customer demands, market conditions, and competitive pressures. To succeed in today's global economy, manufacturers need to have a flexible, agile, and integrated system that can support their entire manufacturing lifecycle, from product design and development to production planning and execution, to cost management and quality control.

Oracle E-Business Suite Manufacturing is a comprehensive solution that provides manufacturers of all sizes, across all industries and regions, with a global business foundation that reduces costs and increases productivity through a portfolio of rapid value solutions, integrated business processes, and industry-focused solutions. Oracle E-Business Suite Manufacturing enables you to:

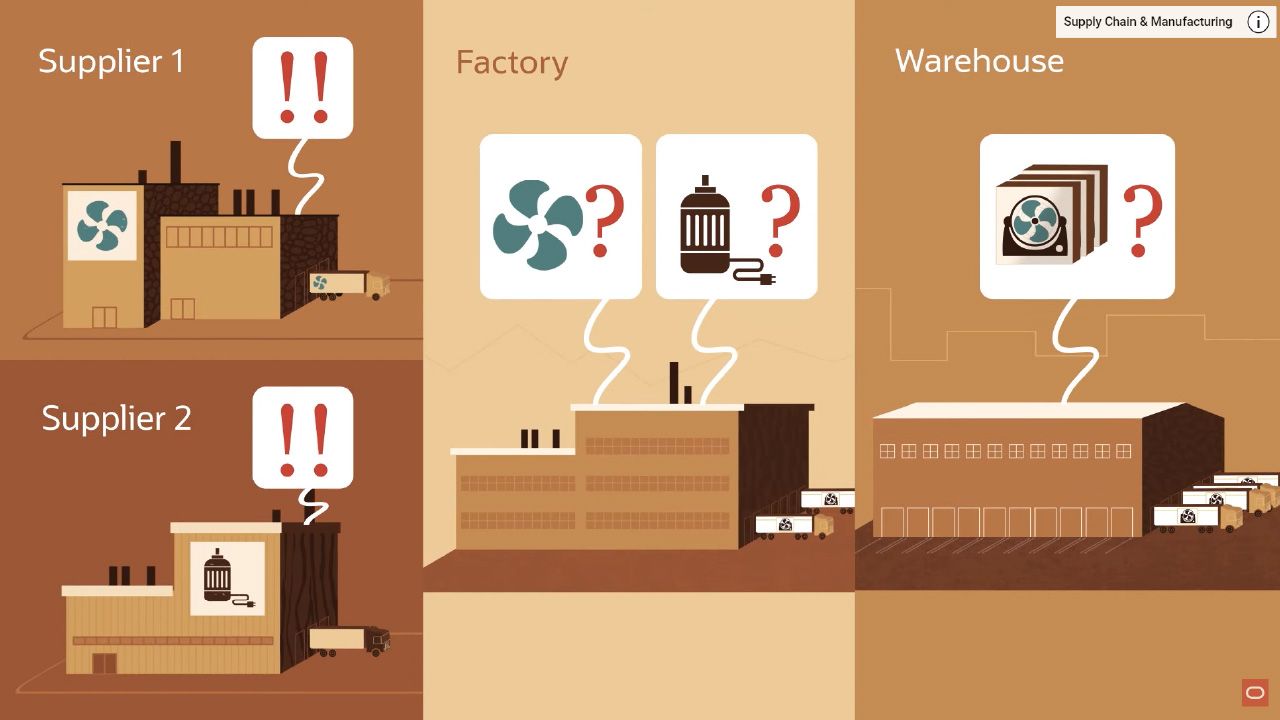

- Manage your global network of plants, suppliers, and customers with a single source of truth for your manufacturing data and transactions

- Orchestrate and execute your production processes with efficiency, accuracy, and visibility, using best-in-class applications for discrete and process manufacturing

- Optimize your manufacturing performance with real-time analytics, dashboards, and reports that help you monitor and improve your key performance indicators (KPIs)

- Leverage the latest technologies such as cloud, mobile, social, and Internet of Things (IoT) to enhance your manufacturing capabilities and competitiveness

The key components of Oracle E-Business Suite Manufacturing

Oracle E-Business Suite Manufacturing consists of several modules that cover the different aspects of the manufacturing lifecycle. These modules are:

- Production Process Design: This module allows you to design and manage your production processes using work definitions, which are the master data that define the inputs, outputs, operations, resources, and costs of producing an item. You can create work definitions for discrete or process manufacturing, using web-based interface tools or spreadsheet templates. You can also manage work definition versions, synchronize item structure changes, calculate lead times, and enable electronic signatures and records for work definition management.

- Production Management: This module allows you to plan, schedule, execute, monitor, and close your work orders, which are the transactions that initiate and track the production of an item. You can create work orders for standard or configured items, using manual or automatic methods. You can also manage work order operations, materials, resources, outputs, serials, reservations, history, mass actions, material availability, direct procurement of materials, contract manufacturing, configured item work orders, supplier operations, electronic signatures and records for work order approval, audit trail for work orders, and work order closure.

- Manufacturing Execution Systems: This module allows you to integrate your shop floor systems with Oracle E-Business Suite Manufacturing using standard interfaces or custom adapters. You can capture shop floor data such as material transactions, resource transactions, quality results, genealogy information, lot attributes, and serial numbers from various sources such as barcode scanners, RFID readers, PLCs, and MES applications. You can also monitor your shop floor activities using infolets, which are interactive tiles that display key information such as work order status, material availability, resource utilization, and quality metrics.

- Cost Management: This module allows you to track and analyze your manufacturing costs using standard or actual costing methods. You can collect cost data from various sources such as work orders, material transactions, resource transactions, overhead rates, and exchange rates. You can also perform cost calculations, variance analysis, inventory valuation, profitability analysis, and cost accounting entries.

- Inventory Management: This module allows you to manage your inventory across multiple organizations, locations, and subinventories. You can perform inventory transactions such as receipts, issues, transfers, returns, adjustments, and cycle counts. You can also manage inventory attributes such as lot numbers, serial numbers, revision levels, and expiration dates. You can also use advanced features such as min-max planning, reorder point planning, kanban replenishment, consignment inventory, vendor managed inventory (VMI), and mobile inventory.

- Quality Management: This module allows you to ensure the quality of your products and processes using quality plans, specifications, tests, results, actions, and audits. You can define quality requirements for items, suppliers, customers, work orders, operations, resources, and shipments. You can also collect quality data from various sources such as shop floor systems, inspection stations, laboratories, and handheld devices. You can also analyze quality data using charts, reports, and alerts. You can also initiate corrective and preventive actions (CAPA) to resolve quality issues.

How to learn more about Oracle E-Business Suite Manufacturing

If you are interested in learning more about Oracle E-Business Suite Manufacturing and how it can help you optimize your production processes and achieve operational excellence,

you can visit the following websites: